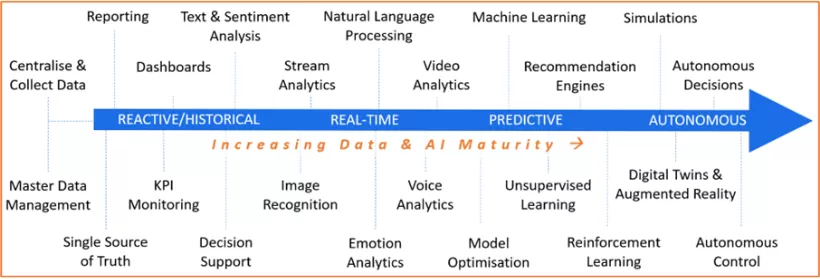

The adoption of Artificial Intelligence and Machine Learning in mining, mineral processing, and energy is a game-changer in the industry. Providing solutions in increasing yield and speed, improving production workflows, operational efficiency and most significantly improving the safety of workers.

In recent years, there has been a shift in attention focused on safety practices and the ambitious target of zero harm. This has driven considerable improvements in safety procedures and risk management techniques used to identify, measure, and address safety hazards.

AI and ML adoption has been valuable in achieving better ways to capture, analyse, and share safety data, identifying meaningful safety indicators as well as high-risk areas and situations. More importantly, it has given mining and energy companies the ability to monitor real-time its operation allowing immediate intervention in high-risk situations and predicting potential safety hazards.

Monitor Real-time IoT and Machine Vision-based alerts (including personal protective equipment, hazards, and mobile equipment risk) to ensure safety compliance. Use Digital Twins for real-time visualisation and scenario modeling.

Predict OH&S incidents by creating forward-looking machine learning-based ‘Dynamic Employee Risk Profiles’ to calculate employees’ chances of being involved in an incident on any upcoming day.

Prevent incidents by retraining, proactively removing employees from potentially dangerous situations, and sending live compliance alerts to employees to immediately eliminate dangerous working conditions.

Machine Vision Based Monitoring

We can expedite the delivery of your outcomes using IP and accelerators.

Artificial Intelligence, ML, Machine Vision, and Data Science-based mining circuit optimisation, using real-world physics simulators, deep learning (ML), and gaming engines to understand and monitor mining circuit inputs, settings, and materials to optimise throughput. Sensors can also be deployed to monitor asset health and alert operators for conditions that typically preceded downtime events in the past. Similar projects generate ROIs greater than 900% or $90m annually in some cases.

IOT-based Location Awareness and Analytics to understand team locations, asset utilisation, and interactions. This results in the optimisation of plant, equipment, and people (including cost reductions, time-saving by minimising proximity for next likely use, scheduled cleaning, and maintenance).

Predict catastrophic equipment failure that could lead to injury or fatality by understanding causes of failure, the likelihood of failure, and predict failure events. Identify defective equipment using machine vision and IoT and determine safe asset use via statistical analysis and optimise asset safety. Use Critical Control Monitoring to identify asset and process failures in advance.

Various surveys across mining to identify areas of risk or concern based on questions around Risk Culture, Safety Culture/Compliance, Engagement and Phycological Health. Results facilitate drilling to problem departments, locations and sited to focus training and remediation activates and maximise training/remediation outcomes.

Machine Vision to generate and deliver automated building and site progress data and safety insights. The project involves using robots, drones, and other autonomous equipment to monitor sites to minimise human movement/risk and maximise reporting accuracy

We’ve collectively delivered exceptional value/ROI in Mining and Resources

Dr. Joe Walsh

Physics, PHD, Dip. Management, Dip. QA; Over 50 International Presentations, Over 100 Peer Reviewed Research Papers;

Head of Data Science and Data Engineering

Kris Hampel

Eng (Hons) Major in Mining Engineering; Various mining roles including Drill & Blast Engineer (Downer EDI), Engineering Consultant (MEC Mining)

Project Lead and Technical Consultant

Rad Anandakumar

Comm, MBA, GAICD; Various mining projects (South 32, Newcrest, FMG, MMG, St Barbara, Evolution Mining, RIO, PYBAR, Anglo Gold, Adaro)

Management Consultant & Data/AI Strategist

Get in touch with AI Consulting Group via email, on the phone, or in person.

Send us an email with the details of your enquiry including any attachments and we’ll contact you within 24 hours.

Call us if you have an immediate requirement and you’d like to chat to someone about your project needs or strategy.

We would be delighted to meet for a coffee, beer or a meal and discuss your requirements with you and your team.